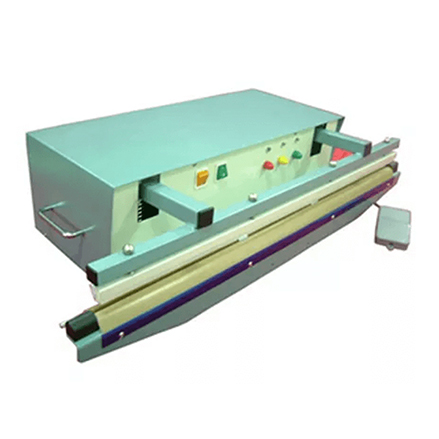

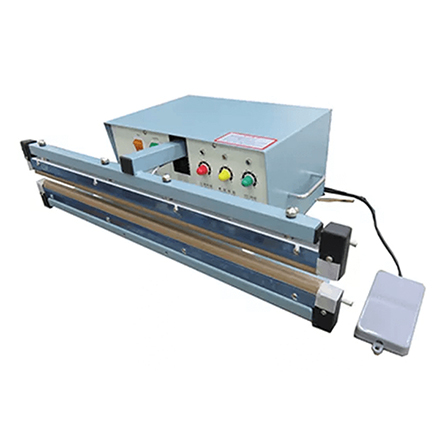

Electromagnet Control Sealers

Wu-Hsing made electromagnet control sealer is designed for the continuous sealing of polyethylene and polypropylene materials, double-sides for Gusset (folded) bags.

Constant heat (direct heat) sealing for Nylon, Alum., Kraft paper.

It is controlled by a stronger electromagnet and foot switch for manual operating.

Impulse sealing:

- Sealing width : 2.7mm/5mm/10mm

- Available size : 300 ~750mm

- Single sealing : PE, PP, OPP, PVC, POF, plastic materials etc.

- Double-sides sealing : Alum, Gusset (folded) bags

- Optional device : Stainless steel-SUS#304 (Direct heat sealer not suitable), Date Imprinter, 10mm sealing, Start Button, Emergency stop Button

For Constant heat (direct heat) sealing:

- It is ideal for Alum. Nylon, Kraft paper

- Wider sealing line: 10mm, 15mm

- Temperature control

*Is having a beautiful mesh and lines seal.

*Warm up time : 7-10 minutes.

How does Electromagnet control Sealer work?

- Once the correct timer (sealing time & Congealing time) settings have been programmed, Foot switch for manual operation.

- Congealing time is necessary for impulse sealing.

- With one stronger Electromagnet offers a uniform pressure to save effort.

What are the benefits of an Electromagnet control Sealer?

- Congealing time is set up for a perfect and durable sealing for impulse sealing.

- No need to connect the air compressor

- Powerful Electromagnet. Save effort

- Can be used everywhere